Combined Heat and Power (CHP) is not a new idea to the UK. Woking for example, has a large district heating network which makes considerable carbon savings and the Immingham plant on the Humber is a large industrial example. Yet when one compares the UK to Sweden, UK CHP seems very underdeveloped in comparison. Here we would like to discuss just what makes Swedish CHP so great and what the future holds in the UK for the technology.

Combined Heat and Power (CHP) is not a new idea to the UK. Woking for example, has a large district heating network which makes considerable carbon savings and the Immingham plant on the Humber is a large industrial example. Yet when one compares the UK to Sweden, UK CHP seems very underdeveloped in comparison. Here we would like to discuss just what makes Swedish CHP so great and what the future holds in the UK for the technology.

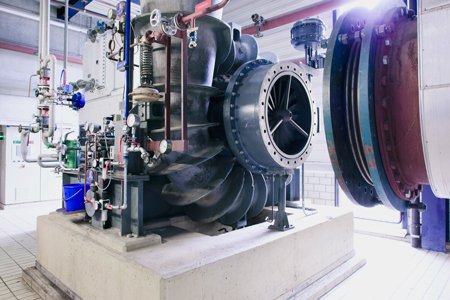

We won't cover the technical aspects to CHP cogeneration here, as just an introduction is needed. The principle is simple however; whether on a micro scale or on an industrial scale, power production and industrial processes usually create a lot of heat, which is wasted ''potential'' energy. CHP cogeneration aims to take this waste heat and make it useful, increasing the efficiency of the installation. Often this will mean piping the heat to nearby buildings to be used for domestic, industrial heating, or even, additionally [by the use of Absorption Chillers] chilled water for air conditioning! Known as TRI-Generation

Example of Sweden – wide adoption of combined heat and power technology

For the best examples of these ideals, Sweden is an excellent place to look. Here, around two thirds of heating requirements are provided through renewables in the form of biofuels, waste materials and sustainably sourced electricity. Additionally, district heating is widely implemented there, and now accounts for 43% of heating consumption. Biomass is considerably more common generally, which makes an excellent low carbon combination with district heating. But what is special about the country to make these technologies so much more widely implemented however?

Perhaps most importantly, the Nordics have long taken on board the need forenergy efficiency due to their very cold climate, and coincidentally have policies considerably more proactive for carbon reduction than the UK as a by product. For example, coal burning is extremely expensive due to the huge taxes levied on power stations burning the fossil fuel – the tax can be as much as twice the cost of the coal. The knock on effect this has is to make renewables much more attractive for electricity production. In some instances this has meant more biofuels, but also geothermal and other renewables are found. Both of these technologies lend themselves well to CHP, due to the large quantities of heat they generate.

This is not simply a coincidence however. The region has extremely cold winters, and heating is therefore much more important than in milder climes. As a result, many power stations of this type are ‘thermal leading’, meaning their main purpose is to provide heat rather than electricity. Electricity is more the by-product than heating in some instances.

What does this mean for the UK?

So are the UK and Sweden similar enough to be able to learn from their example, or are the two so different as to make the comparison irrelevant?

Even though we are a milder country, the UK spends around £33 billion on heat across the economy per year and it is the number one reason for energy use. It therefore follows that reducing our heating’s contribution to energy use will coincidentally cut carbon emissions considerably. Of course, a multifaceted approach to reducing this burden is important. Insulation and energy efficiency are imperative, yet CHP cogeneration could offer a way to tackle this problem at the source. Immingham ConocoPhillips refinery is the largest industrial CHP facilities in Europe, located in the north-east of the UK. Woking on the other hand, is a good example of district heating, where its waste to energy plant converts hundreds of thousands of tonnes of waste each year into heat and energy. Running for nearly 25 years, the plant saves around 20,000 tonnes of carbon emissions per year when compared to fossil fuels. The scheme supplies electricity to the grid and helps heat hundreds of the city’s major buildings.

Sheffield also has a great example of CHP working well in an urban environment, yet after a quarter of a century of successful operation, the UK has yet to fully embrace the advantages of CHP as a tool for efficiency and carbon savings.

The DECC last spring released their ‘Heat Strategy’, which has highlighted areas of improvement for the sector. It confirms the need for a change in Britain’s attitude to heat, looking at both supply and demand to reduce energy consumption. On the demand side it proposes 3 major areas for improvement: insulation, efficiency of heat delivery systems and better heat management. On the supply side, the main areas of focus are: low carbon building level heating systems, changing the content of natural gas in the grid and low carbon heat networks. It also specifically mentions the EU market for heat pumps and how the UK can capitalise on this.

So is more UK CHP just around the corner?

Looking at some of the prerequisites for CHP, the UK seems to fulfil them all; the fuel source is there, the technology is already available, the dense urban environments of major cities in the UK lend themselves perfectly to district heating and given the urgent need to new energy solutions, there seems to be an obvious gap in the market for more CHP. Perhaps it is just a cultural barrier that remains. Where northern Europe has embraced the technology long ago, the UK is only now waking up to the fact is needs to rethink its energy and heating policies.